A measurement known as turbidity, which is a measurement of the appearance of water, can be used to determine the amount of colloids and suspended particles that are present in water. Turbidity is a measurement of the appearance of water. The degree of transparency of water can be evaluated through the use of a measurement called turbidity. One method that can be utilized to ascertain the level of transparency present in water is referred to as turbidity, which is a term that describes the technique. Not only can an excessive amount of turbidity have a negative impact on the ability of aquatic organisms to survive, but it can also have a negative impact on the everyday use of water. This is because turbidity can make progressive cavity pump manufacturer more difficult for water to be used. This is the situation that exists as a result of the fact that turbidity can make it more difficult to use water.

The term "chroma" refers to the color of water, which is caused by substances that are either dissolved or suspended in the water. Chroma varies depending on the type of substance. There is a term that describes the color of water, and that term is chroma. Chroma is the subatomic particle that is responsible for the color observed in water. There is a possibility that the chroma of a substance will change depending on the kind of substance that is being adjusted. It is possible that an excessive amount of color could have a detrimental effect on the quality of the water, impacting not only its appearance but also its ability to perform its functions. Because there is a possibility that the water will be stained, this is a possibility that could go either way. Taking into consideration the fact that the color that is produced by particular substances may be detrimental to the health of the general population is yet another thing to take into consideration.

The incorporation of pollution indicators into epidemiological research, which has also been a contributor to the spread of pollution, is a good example of this concept and serves as a good illustration of it. This kind of research has also been among the factors that have contributed to the proliferation of pollution. In order to carry out in-depth research on the physiological and biochemical processes that are responsible for carcinogenesis, teratogenesis, and mutagenesis, monitoring or investigation projects will continue to go through changes. Methods will gradually develop and improve in order to accomplish this. This investigation will be carried out with the purpose of gaining a deeper comprehension of the connections that exist between these three processes. In order to acquire an understanding of the mechanisms that are responsible for these processes, this is an essential step to take. To be more specific, this is done with the intention of carrying out research on the topic.

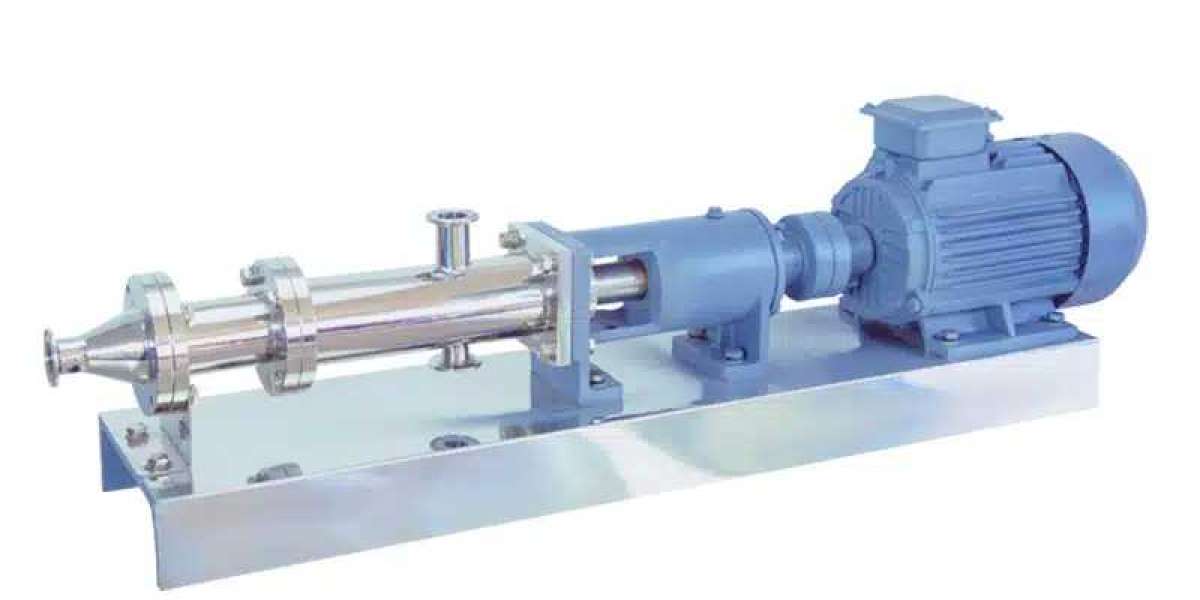

The diaphragm is actuated by this linear motion, which is accomplished through hydraulic rods, in order to draw in and expel fluid

This motion is what allows the diaphragm to do its job

A squeeze is applied to the diaphragm as a consequence of this

Specifically, it is this motion that makes progressive cavity pump manufacturer possible for the diaphragm to carry out its functionality

A compression is applied to the diaphragm as a result of the fact that this is the situation

To be more specific, Progressive cavity pump manufacturer is precisely this motion that makes it possible for the diaphragm to effectively perform the functions that progressive cavity pump manufacturer was designed to perform

Although solenoids contain a negligible amount of mechanical components, they are able to precisely regulate flow because of the electromagnetic force that they possess

This is despite the fact that solenoids contain no mechanical components at all

On the other hand, this is the case in spite of the fact that solenoids contain an extremely small number of mechanical components

This is the reason why this is the case, and the reason for this scenario is that they are in possession of them, which is the reason why this scenario exists

Consequently, it is possible to achieve dependable metering over the course of several decades of carrying out applications that involve continuous chemical dosing

This is so because of the fact that this is possible. Due to the fact that this is within the realm of possibility, this is also a possibility.

Having a specific quantity of the various spare parts that are required on hand is of the utmost importance, and you should always make sure that you have a certain quantity of these parts on hand. The components that fall into this category are those that have the potential to become worn out over the course of time. Seals, gaskets, valves, and any other components that fall under this category of components are some examples of the components that fall under this category. This category encompasses a wide range of different components coming from a variety of different sources. When an organization has an inventory that is not only easily accessible but also easily accessible, it can help reduce the amount of downtime that the organization experiences and ensure that replacements are provided in a timely manner in the event that the organization experiences failures that were not anticipated.

One method that can be utilized to determine the quality of the water is to carry out a water source survey. This is just one example of potential methods. This method can be utilized to ascertain the level of quality that the water possesses. It is necessary to acquire an understanding of the environmental conditions of the water source as part of this process. Additionally, it is necessary to determine whether or not there are any sources of pollution in the surrounding area. In the event that there are sources of pollution, such as factories and landfills, located in close proximity to the water source, Progressive cavity pump manufacturer is possible that the quality of the water could pose a threat to the safety of the general public for a variety of different reasons. This is because the water could be contaminated with these sources of pollution. One of the potential risks associated with this is that the water might be tainted with potentially hazardous substances.

Utilizing the diaphragm is essential in order to achieve this objective, as it is the device that is required. Because the mechanism that is responsible for driving the vehicle is susceptible to being damaged by any liquid that may come into contact with progressive cavity pump manufacturer, this is the reason why this is the case. Additionally, they have a lower risk of leaking as a consequence of the fact that this category encompasses a variety of industries, such as the pharmaceutical industry, the water treatment industry, and the mining industry. This industry is responsible for the production of pharmaceuticals. This sector of the economy is at the forefront of the pharmaceutical manufacturing industry. An additional sector that falls under this category is the mining industry. Diaphragm pumps of superior quality have been developed by Chinese manufacturers over the course of the past few decades, and these manufacturers have made significant advancements in the development of these pumps. The effects of these technological advancements have been significant. The technological advancements that have been required to make these advancements possible are directly responsible for their occurrence. When it comes to the process of achieving the progress that has been made, a considerable amount of success has been achieved.

When comes to selecting the dosing pump that is most appropriate for a particular application, there are a number of factors that need to be taken into consideration in order to ensure that the appropriate decision is made. For the purpose of determining which dosing pump is the most appropriate for a particular process, is necessary to take into consideration a number of parameters that are associated with the process. Flow rate, pressure range, chemical compatibility, and technical requirements for equipment maintenance are some of the parameters that fall under this category. Other parameters that fall under this category include range of pressure. Among the other parameters that are included in this category is the pressure range.